SuessCo wind turbine monitoring

ensures efficient analyses and increases operational reliability.

High-tech sensors for digital monitoring of wind turbines and infrastructures.

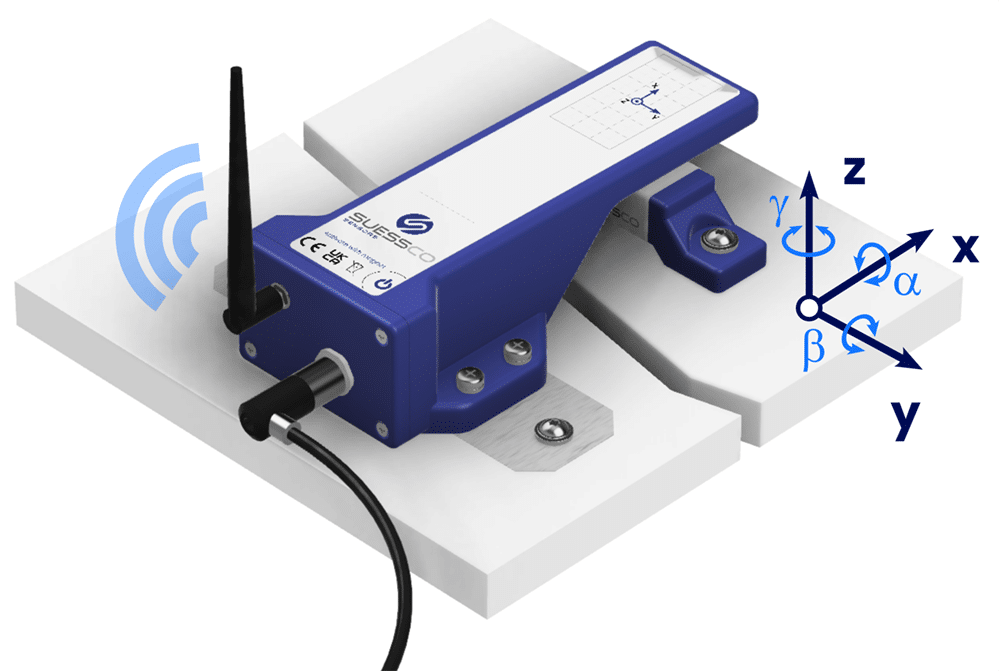

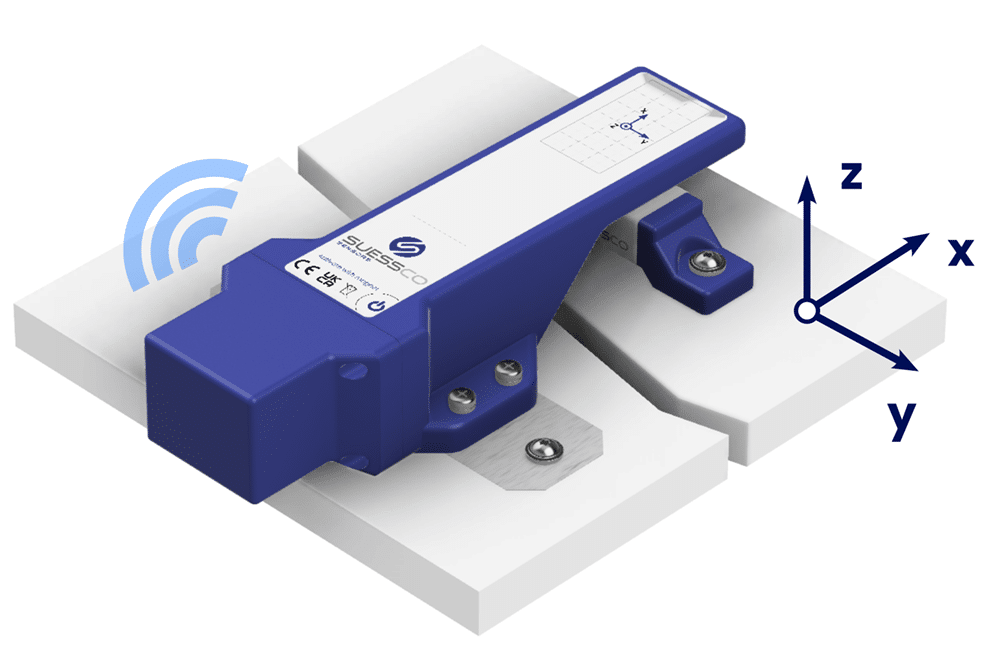

Monitor your wind turbines precisely with the SuessCo 6D sensor. Our patented magnetic field technology detects movements and cracks at critical points such as foundations and transitions in real time. The resulting data enables precise analysis of the condition so that maintenance measures can be initiated in good time. Rely on significantly increased operational safety to detect risks at an early stage and ensure the stability of the system in the long term.

Advantages

Motion monitoring

Continuous detection of even the most minimal movements to develop maintenance strategies

Innovation

Patented magnetic field technology for superior performance in 6 dimensions.

Increased safety

Prevents hazards through continuous monitoring and alerting.

Efficiency

Reduce on-site inspections and costs while increasing the safety and service life of your infrastructure.

Long-term monitoring

Provides precise data for long-term analysis and maintenance.

Reliability

Developed for extreme conditions and long-term use over many years.

What our customers say

"Previously, we inspected the bridge bearings on site. With the SuessCo 6D sensors, we always have up-to-date measured values available. That's our advantage, it saves us costs of course and it's higher quality."

Georg Gotthart

Bridge construction technician, ÖBB

Sensor installation in 4 steps

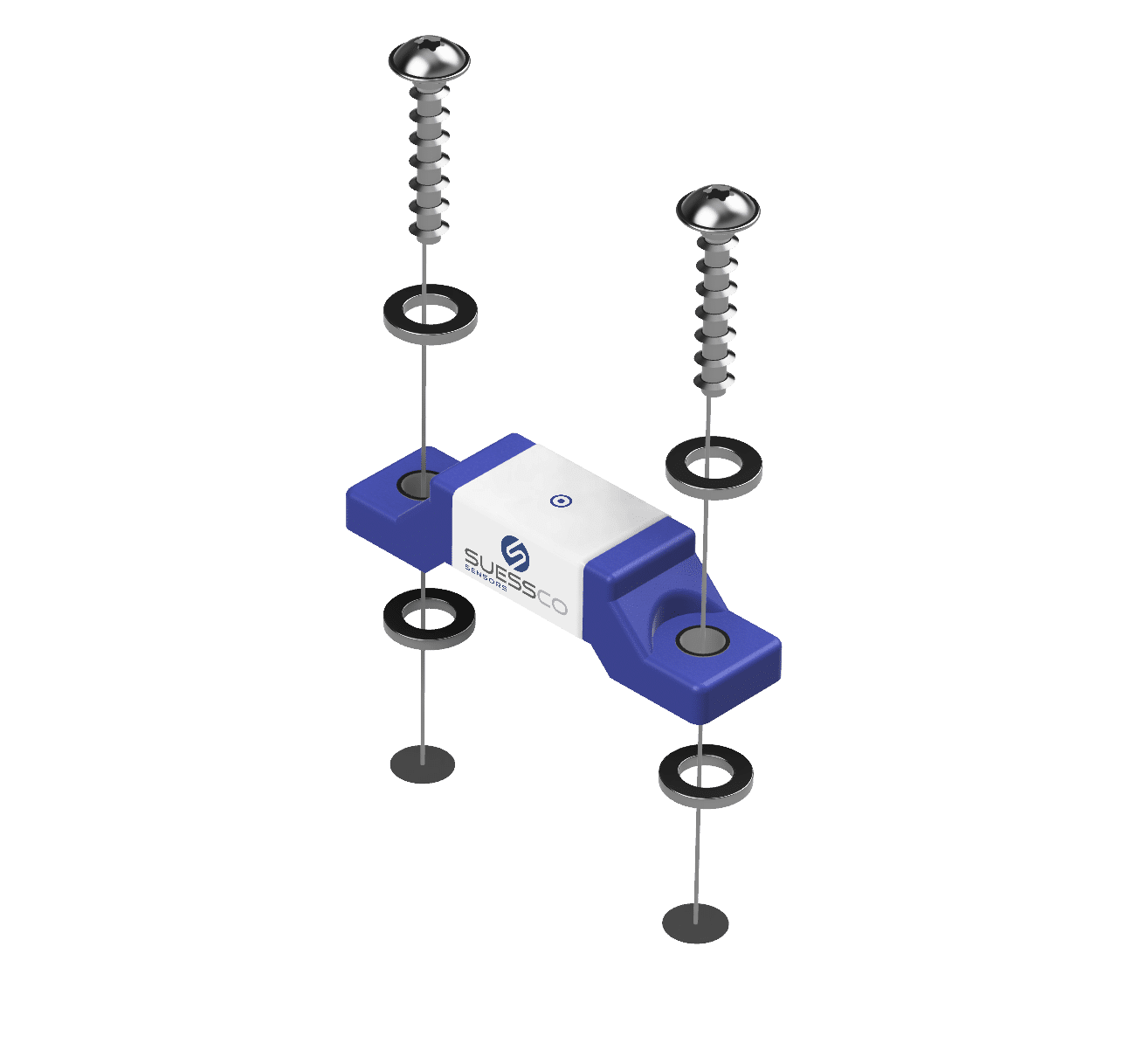

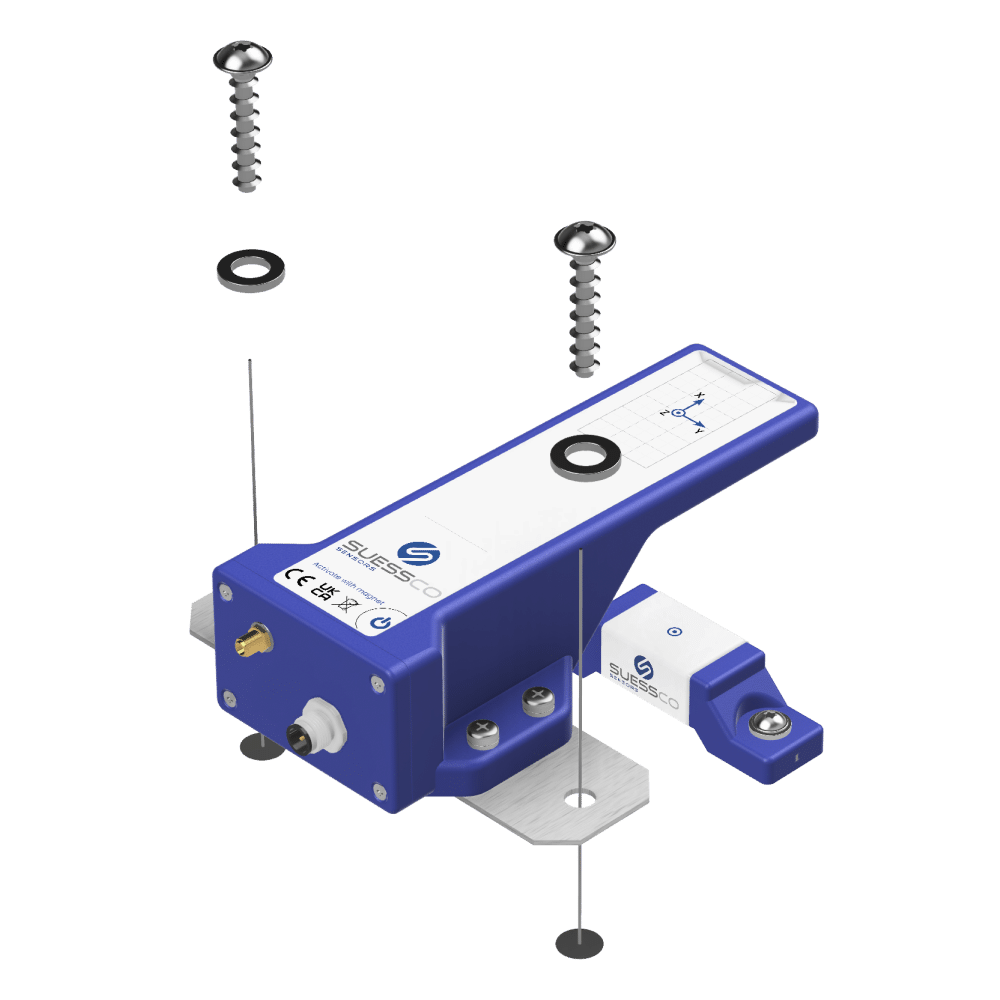

Install reference object

Install the sensor

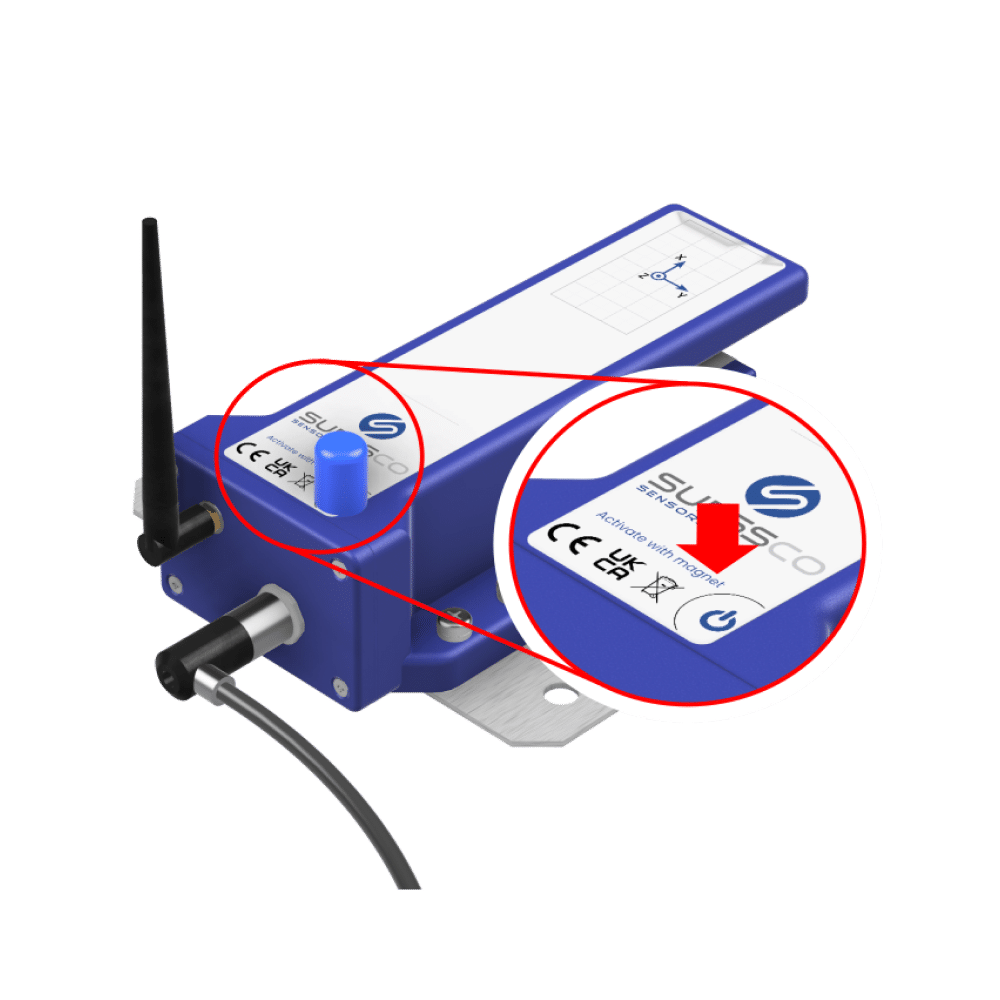

Activate with magnet

Analyze data

Innovative solutions that convince.

Applications

FAQ

The SuessCo 6D sensor system is particularly user-friendly and efficient to install. It is designed for flexible installation at various monitoring points and, thanks to wireless data transmission, no complex cabling is required. This shortens the installation time and the monitoring system is quickly ready for use.

The system ensures precise monitoring and analysis by detecting even the smallest movements in real time. It enables early action to be taken, reducing maintenance costs and downtime, thereby increasing the safety and service life of structures. Wind turbine monitoring is thus redesigned and made particularly user-friendly.

The 6D technology captures movements in six dimensions, including three spatial directions and rotational movements. This precision is ideal for demanding monitoring requirements, as it enables detailed analysis of structural changes and immediately identifies potential risks. Therefore, they are perfect for critical infrastructures where safety plays a particularly important role.

Contact

"*" indicates required fields